New Production Run |

Top Previous Next |

Bill of Materials (BOM) - Creating a New Production Run

Accessing the Bill of Materials

1.Navigate to Stock Items > Extra > Bill of Materials. The Bill of Materials Lookup window will open.

2.Right-click the item to manufacture and select New Production Run.

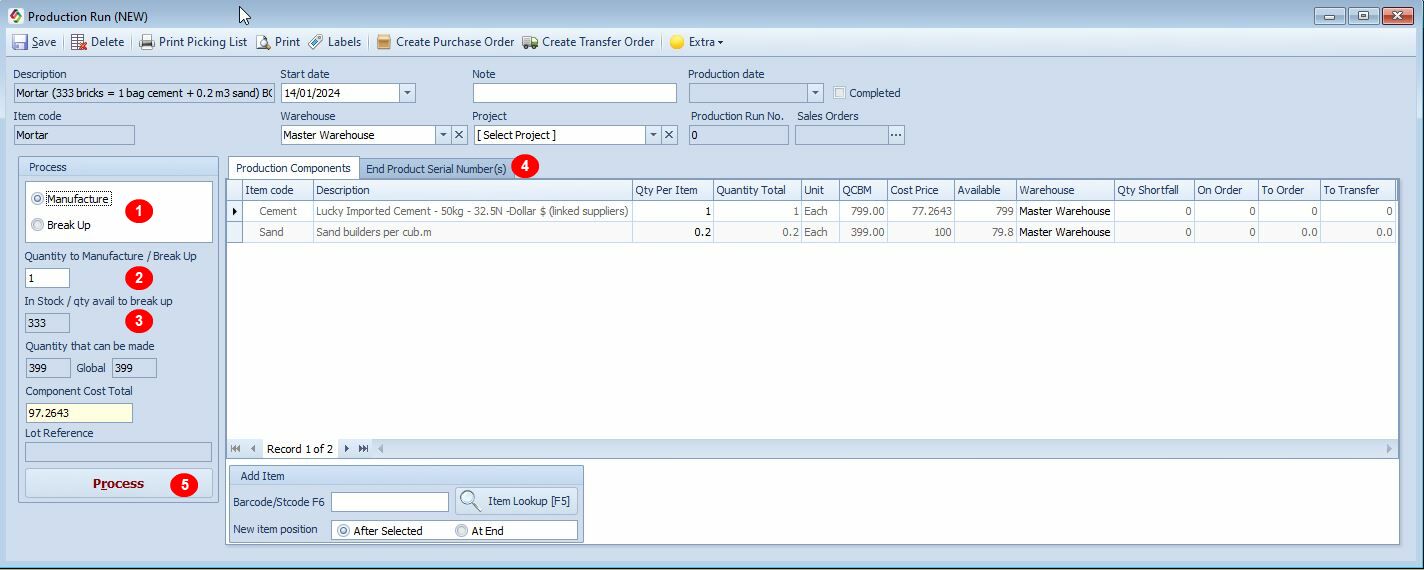

Steps to Manufacture or Break Up an Item

1. Choose between Manufacture (create a new item) or Break Up (reverse-manufacture an item).

2. Enter the Quantity to Manufacture or Quantity to Break Up.

3. Verify sufficient stock is available for the selected quantity.

Note: The following details are displayed to assist you:

• Quantity available to Break Up: Previously manufactured items in stock and available for breaking up.

•Quantity that can be made: Maximum quantity manufacturable based on stock in the current warehouse or across all warehouses (if global stock is considered).

•Component Cost Total: Total cost of the manufactured item based on its components.

4. If applicable, input all required serial numbers.

5. Click Process to complete the manufacture or break-up action.

Note: You can't Process the Production Run if Packing Required is enabled.

Process Production Run

Sales Order Field: If initiated from the Sales Order Detail form, the associated Sales Order Number will display in the Sales Order field.

BOM: Packing Required (If Needed)

Packing and unpacking Production Run can be done from the Production Run Lookup screen. This ensures that only the correct stock and quantities are issued to the customer — a useful security measure.

Steps:

1. Set Allocation Mode:

•Go to Stock Items > Stock Options > Allocation tab and set Production Run Allocation Mode to Manual if you want to reserve items.

2. Save the Production Run.

•A Production Run Number will be assigned.

•Quantities will be reserved and shown in the Stock Main Form (click the ? next to the Reserved field).

•The BOM Lookup – In Production column also shows what is currently in production.

3. Allocate Quantities:

•Quantities are automatically allocated.

•If not, go to Extra (Menu Bar) → Allocate Where Possible.

4. Open the Production Run Lookup form.

5. Right-click the Production Run → Select Pack or click Packing Screen (menu bar)

6. Scan the items to be packed.

7. Click Process to confirm the packing.

8. Finalize:

•Go back to Production Run Lookup, right-click the Production Run No., select Open Production Run, then click Process to finalize.

New Production Run Menu Bar - The menu bar provides the following options |

|

Save |

Save the production run without processing for later completion. Saved runs will appear in the In Production column of the Bill of Materials Lookup form.

|

Create Purchase Order |

Create a Purchase Order from the BOM Production Run screen. Automatically generates a purchase order based on quantities listed in the To Order column.

|

Create Transfer Order |

Create a Transfer Order from the BOM Production Run screen. Automatically generates a transfer order based on quantities listed in the To Transfer column.

|

Approve |

Production Run Approval (If Required) The Approve button will only be visible when the Production Run - Approval Required is enabled.

Steps:

1. Enable the approval setting in Stock Options > Manufacturing tab. 2. Open the New Production Run form. 3. Click the yellow lock on the Quick Access Toolbar 4. In the security form, select the Security Group (e.g., Sales) to grant permission to approve the production run. 5. Click the Approve button in the menu bar. 6. A pop-up form will appear. The authorized person must enter their Employee Number and Password. 7. The Approved By field will populate with the approver’s details. 8. Click Process to complete the production run.

|

Key BOM Production Run Fields Explained |

|

Quantity to Manufacture / Break Up |

Specify the quantity to produce or disassemble. Choose Manufacture to create items or Break Up to reverse-manufacture, reducing the finished item quantity and increasing raw material quantities.

|

In Stock / Qty Available to Break Up |

Displays the quantity of previously manufactured items available in stock for breaking up.

|

Quantity That Can Be Made |

Shows the maximum quantity that can be manufactured based on available stock in the current warehouse or across all warehouses (if global stock is considered).

|

Component Cost Total |

Total cost of the manufactured item based on its components.

|

Columns in the BOM Production Run Form |

|

QCBM: Quantity That Can Be Made |

Maximum quantity manufacturable based solely on this item’s on-hand stock. Calculated as: Available ÷ Quantity Total.

|

Available (On Hand - Reserved) |

Stock available in the current warehouse, excluding reserved quantities.

|

Shortfall |

Quantity needed to meet the production requirements.

|

On Order |

Quantity currently on order with suppliers.

|

To Order |

Quantity required to fulfill production. Use Create Purchase Order to auto-populate a purchase order with these quantities.

|

To Transfer |

Quantity available in other warehouses for transfer. Use Create Transfer Order to auto-populate a transfer order with these quantities.

|

Additional Notes

•Starting a BOM Production Run from a Sales Order: If initiated from the Sales Order Details form, the associated Sales Order Number will appear in the Sales Order field of the production run window.

•Viewing BOM Items: Use the Item Item Extended Lookup form to view all BOM or manufactured items and their in-stock quantities. Apply filters as needed for specific views.