Stock Extra: Bill of Materials |

Top Previous Next |

Hover the mouse over the different fields on the form. If the cursor changes to a hand (![]() ) , click to get more information.

) , click to get more information.

![]()

Bill of Materials: Manufacturing

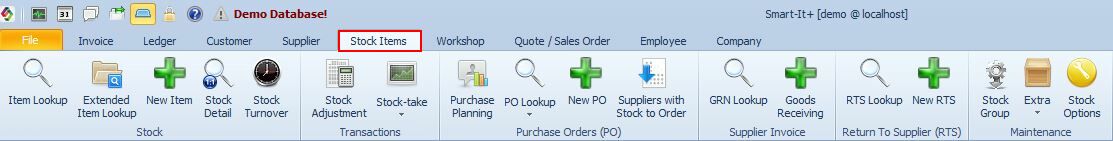

Go to: Stock Items > Extra > Bill of Material

A Bill of Materials (BOM) is a comprehensive recipe that combines raw materials, sub-assemblies, intermediate assemblies, sub-components, and components into a finished inventory item. It ensures precise tracking of quantities and costs throughout the manufacturing process.

Key Benefits:

•Accurately calculates production costs based on component usage.

•Supports efficient inventory management by deducting raw materials when producing finished goods.

•Enables scalable manufacturing for simple or complex products.

Before You Begin: Check These Settings

Navigate to: Stock > Stock Options.

Review and configure these options to align with your business needs. Incorrect settings can lead to stock discrepancies or costing errors.

Setting |

Description |

Recommendation |

Allow Negative Stock

|

Permits manufacturing even if raw materials are insufficient (system allows negative quantities). |

Not recommended – Can distort inventory reports and costing. Use only for emergency production. Tip: Enable temporarily if needed, then disable to prevent ongoing issues. |

Strict BOM

|

Locks the BOM structure and quantities when Stock On Hand (SOH) > 0. Prevents edits until SOH = 0. |

Highly recommended for accurate costing and stock control. Common Mistake to Avoid: Attempting BOM changes with existing stock – resolve by issuing or adjusting stock to zero first.

|

Key Features and Steps

Access the BOM module via Stock Items > Extra > Bill of Material. The main interface includes:

•BOM Lookup: Search and view existing BOMs.

•Bill of Components: Define or edit the list of materials and quantities.

•New Production Run: Initiate manufacturing based on the BOM.